|

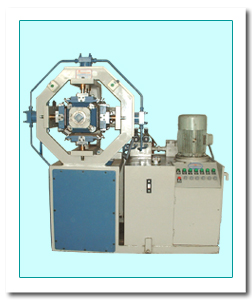

HYDRAULIC STRETCH

FORMER

STRETCH

FORMING M/C is used for making 16 Liters square tin

containers from circular seam welded container, with the

additional making forming, side stiffening, embossing & vertical

ribs.

The machine basically consists of two parts.

1. The die & forming device driven by hydraulic cylinders,

2. The hydraulic power pack (pressure control unit) to operate

the die.

THE DIE:

The die consists of four arms operated by one hydraulic

cylinder, which stretch the circular can into the square form.

The mandrel remains still, with four male projection plates for

the purpose of embossing. The machine is also fitted with four

slides surrounding the still mandrel which carry matching female

grooves. The slides are hydraulically operated by four hydraulic

cylinders.

Monogram/symbol embossing can also be combined with operation

(at extra cost).

POWER PACK:

The power pack consists of a hydraulic pump driven by a totally

closed 7.5 h.p. induction motor. The pump is capable of

developing pressure of 175 bar kg/cm. sq. The power pack also

consists of a pressure control unit with two relief valves.

| Model No.

|

: |

GS-SF |

|

Forming & Streching Cap. |

: |

Adjustable to 15 Kg Size |

|

Working Capacity |

: |

Approx. 20 Tins per min |

Overall Dimensions

H X W X L |

: |

1465 X 890 X

1447 |

|

Input Power Supply |

: |

5.5 KW (7.5 HP) |

|

Control |

: |

Electronic (Timer)

Hydraulic

(Solenoid Operated Valve) |

|

Oil Capacity |

: |

270 Ltrs. Approx. |

|

Hydraulic Pressure |

: |

1000-3000 PSI |

|

Net Weight |

: |

1500 Kg. Approx. |

|

|